Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

From Bluetooth-enabled toothbrushes to smart lightbulbs, more and more everyday electronics are converting to Internet of Things (IoT) devices. As this trend grows, the size of the Printed Circuit Boards (PCBs) that serve as the "brain" of such electronics is shrinking.

The shrinking PCB, paired with the desire to add more information to barcode labels used for product traceability, has introduced a new challenge — the need for a small barcode label that remains decodable at the smallest of font sizes. For years, manufacturers have turned to traditional thermal transfer (THT) labels to create their barcode labels, but have discovered that as the font gets smaller it begins to distort.

So, what’s the alternative? Some manufacturers are turning to laser markable labels for jobs that require smaller PCB labels and fonts because laser marking retains its crisp resolution at even the smallest of font sizes.

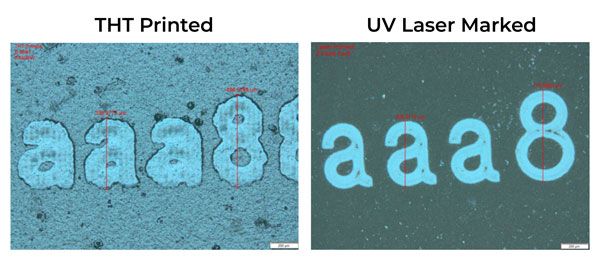

Can you see the difference?

At 50x magnification, the laser marked sample still retains its crisp resolution while the thermal transfer image begins to distort at 5 pt font and smaller. The example uses 2 pt font.

Laser markable labels are a great solution when your PCB barcode label needs a greater resolution or additional abrasion and chemical resistance.

This technology uses a subtractive process that allows printed layers to be more highly crosslinked, creating a more permanent identification for a coated product. Due to this, laser markable labels are more chemical and abrasion resistant than typical THT labels.

Because the printed information is ablating the coating using infrared or UV lasers, the print resolution can also be extremely high and is only limited by the beam quality and focal optics of the laser system employed. ANSI “A” and “B” barcode grades are easily obtained using these materials. The resolution can reach up to 1200 dpi, which allows for small font applications at two point font and below.

THT printing has been a popular option for PCB manufacturers due to its lower cost and industry preference for using white labels that exhibit black indicia. When first introduced, many of the laser markable solutions were black PCB labels that show white indicia. As a result, some PCB manufacturers have requested a durable, laser markable white PCB label that displays black indicia.

In response, Brady has developed both white and black laser markable labels, explicitly designed for PCB and component marking, that are compatible with commonly-used laser marking systems. Our laser markable options include:

However, white laser markable labels presented an additional challenge during development. Unlike black colored labels, white colored labels are naturally reflective, which limits the laser’s effectiveness in transferring energy.

Furthermore, white laser markable products created by other label manufacturers typically incorporate white pigments and / or fillers in order to achieve an appropriate amount of “hide” for the subsequent darker layer within the construct. In many instances, these materials are thermally stable at temperatures that far exceed what the laser output can achieve, providing a source for debris generation.

Understanding how detrimental debris can be during the manufacturing and assemly process of PCB boards, our experts were determined to create a white-colored laser markable label that was debris-free. Brady now offers a patent-pending white laser markable portfolio that cleanly ablates when using both CO2 and UV type laser systems.

Figure 1

A comparison of debris generated after laser marking a competitive white, laser markable product with a CO2 laser vs. Brady B-732A material (white gloss laser markable polyimide) that remains debris-free. In this example, a piece of clear tape is placed over the laser marked area in order to capture the debris generated during the ablation process.

Brady laser markable materials incorporate proprietary coatings that endure difficult-to-survive conditions, including high-temperature reflow steps for surface-mount technology (SMT) and washing steps that limit the use of traditional thermal heat transfer (THT) print.

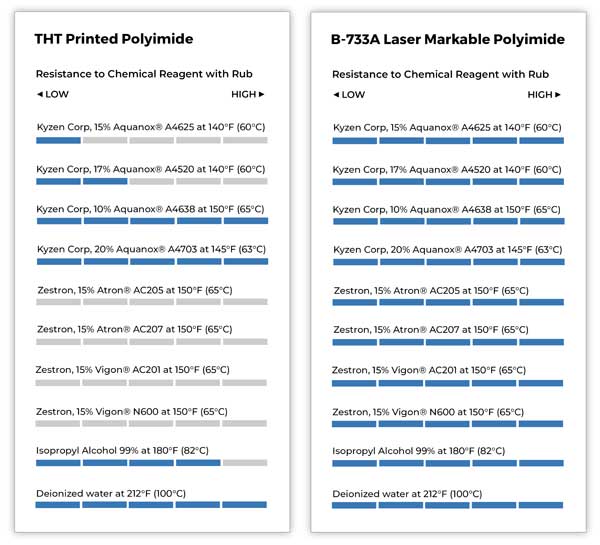

Figure 2

Chemical reagent with rub testing comparison between a traditional THT printed label and a Brady laser marked label.

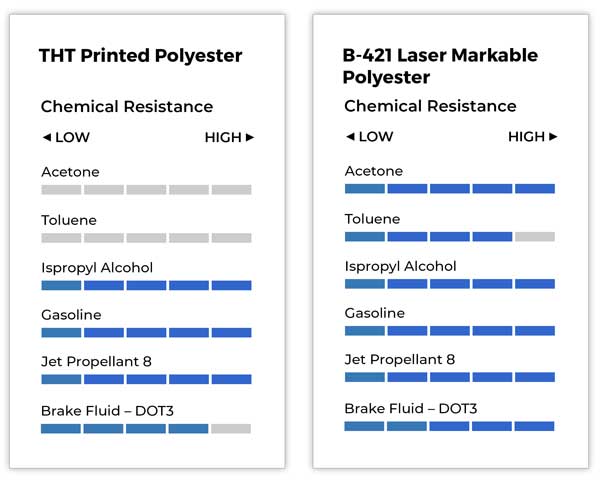

Figure 3

Chemical reagent with rub testing comparison between a traditional THT printed label and a Brady laser marked label.

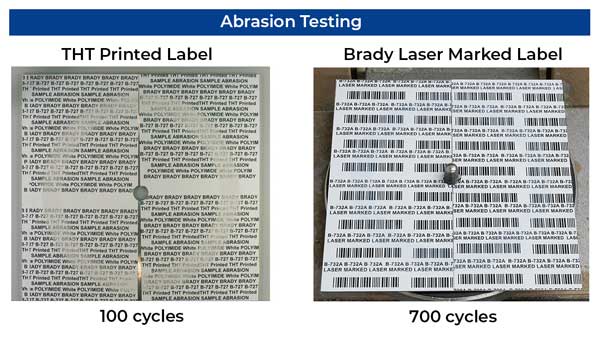

Another advantage of laser marked labels versus THT printing is the superior abrasion resistance. Typically, laser marked labels survive over five times more abrasion than THT printed labels, as illustrated below.

Additionally, manufacturers may wish to more fully automate their labeling jobs along with their pick-and-place, surface-mount technologies. Laser markable labels can be picked, placed and marked in line, reducing the need for additional printing steps.

There’s a wide variety of lasers and accessory equipment available for your laser marking applications; it really comes down to how you plan to use your investment. Equipment manufacturers commonly incorporate fiber diode, CO2 and UV lasers into their production lines to assist with product traceability.

Besides laser type, these systems can also vary in several distinct aspects, specifically power, wavelength, spot size and laser velocity. As a result, the engraving quality is typically dependent on the type of laser, its capabilities and the chemistry of the material to be marked.

Our experts have found that Brady laser markable labels can be effectively used with all laser types, while our laser markable white labels work best with CO2 and UV lasers. However, with the variables mentioned above, we always recommend that you request a sample for testing with your laser marking system to ensure it performs to your company’s standards.

Don't just take our word for it, request samples of our laser markable PCB labels to test using your laser marking system by contacting Brady customer support. Once you find the best option for your unique needs, our laser markable labels are available for order in a variety of sizes and quantities. All of our laser markable PCB labels can be custom ordered by contacting the Customer Support team.

Trademarks

Aquanox® is a registered trademark of the Kyzen Corporation.

Atron® is a registered trademark of the Zestron Corporation.

Vigon® is a registered trademark of the Zestron Corporation.