Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Lean is an improvement philosophy that aims to minimize waste and maximize efficiency in all aspects of an organization. This involves identifying and eliminating non-value-added activities and continuously improving processes. It originated in the manufacturing sector but has been widely adopted in various industries.

In a laboratory setting, Lean principles can be applied to improve efficiency, productivity, cost savings and quality. It’s a powerful tool that can help labs improve operations and achieve goals.

Lean 5S is a methodology that labs can use to create a more organized and efficient workplace. It consists of five steps:

Here’s a breakdown of those five steps along with the solutions Brady offers that support each step.

This step consists of identifying and removing unnecessary items from the workplace. That could include items that are not used regularly, duplicates or obsolete equipment. Once everything is sorted through, one simple solution is to create a designated area for frequently used items.

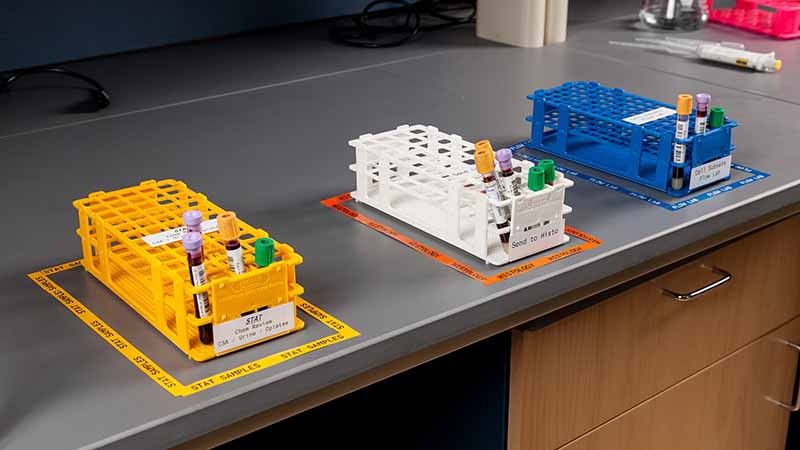

Another solution is to implement a system for storing and retrieving items to keep workspaces more organized. RFID tags can help with this by enabling tracking and identification of lab items so they can quickly be found with improved accuracy.

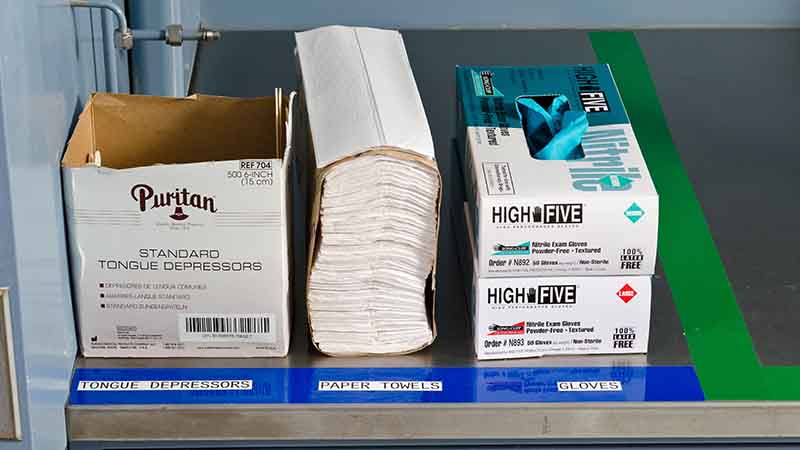

Set in Order is the second step of the 5S lean methodology, and is designed to create a more organized and efficient visual workplace in laboratories. It involves using tools such as labels or floor marking tape to arrange the workplace in a logical way so items can be easily found and used.

Labels can play a big role in organization. Brady has many different lab label printers and label types designed to meet specific requirements of various lab environments that play a crucial role in clear identification and organization. Choosing a label that’s durable and will remain legible will support this step of Lean methodology.

The Shine step focuses on cleaning the workplace and equipment. The goal of this step is to create a clean and organized work environment that is conducive to efficiency and safety. Beyond cleaning, it’s important to inspect equipment for damage or wear and tear and implementing a preventive maintenance schedule to ensure equipment continues to function correctly.

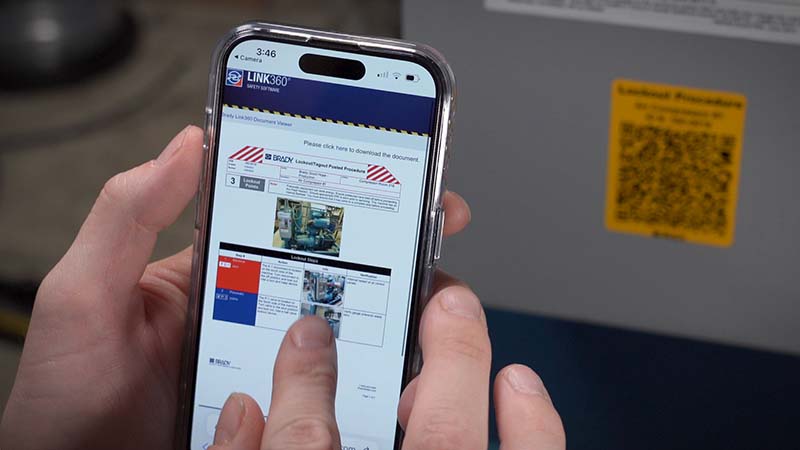

LOTO (Lockout Tagout) equipment can greatly contribute to the Shine step since it’s used to isolate and de-energize equipment during cleaning, inspection and maintenance procedures. In the spirit of Lean methodology, LOTO procedures can be reviewed and improved on an ongoing basis, ensuring that the Shine step remains effective and efficient.

The Standardize step involves creating and maintaining consistent work procedures. This step aims to ensure that all laboratory processes are carried out in a standardized and efficient manner, reducing variability and improving overall quality.

One key element of the Standardize step includes creating standard operating procedures (SOPs) that define processes and describe how all laboratory personnel should perform specific tasks. Another key element is implementing visual management tools like color coding and labeling that helps with quick identification items, equipment and materials. Brady makes pre-printed labels with standardized formatting that can help maintain consistency in the lab.

Sustain is the final step in the 5S Lean methodology. It involves continuously improving the 5S process and ensuring that it becomes a part of the laboratory culture.

To ensure that the 5S process becomes a sustainable part of lab operations, it’s important that labs conduct regular audits to identify areas for improvement; provide employees with ongoing training and education; and involving all personnel in the 5S process by encouraging them to provide feedback or suggestions for improvement.

By putting 5S into action, labs can improve efficiency, reduce waste and create a safer and more productive work environment. Brady has RFID tags, LOTO equipment, labels and more effective solutions for implementing the 5S methodology into your lab. Explore all of Brady's offerings for a more efficient and organized lab environment.

Stop Lab Chaos! Ensure Accuracy & Efficiency with the Right Labels. From chemicals to samples, this guide helps you choose the perfect labels for every application in your lab.

Discover the right lab labels for your needs.

Streamline Your Lab! Master essential practices for sample management & prevent costly errors.

Explore the power of proper lab sample management.

Automate Your Lab & Boost Efficiency. Label faster, reduce errors & free up valuable staff time.

Label smarter, work faster today!